-

-

-

Plot No -18, Tirumala Hans Industrial Park, Indore, India

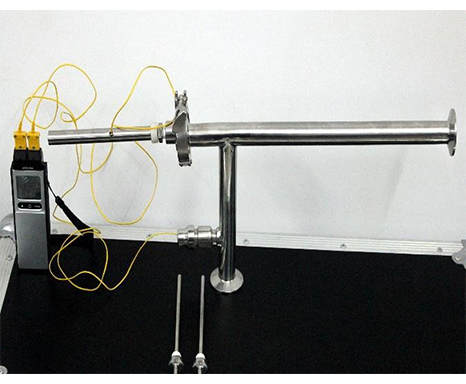

Steam Quality Test / Pure Steam Test

Purity & Performance – Verified in Every Steam Cycle

At Oorja Technical Services Pvt. Ltd., we offer specialized Steam Quality Testing (also known as Pure Steam Testing) to evaluate the physical and thermodynamic properties of steam used in sterilization and critical manufacturing processes. These tests are essential for ensuring that the steam used in autoclaves, sterilizers, and cleanroom environments meets the EN285, HTM 2010, and ISO 17665 standards, ensuring both equipment performance and product sterility.

We help pharma, biotech, and healthcare industries validate that the steam being used is free of contaminants and maintains the right phase and properties for efficient sterilization—thus meeting both regulatory and GMP compliance.

Our Steam Quality Testing Covers:

- Non-Condensable Gas (NCG) Test

Measures the amount of air and gases that do not condense in steam, which can hinder sterilization by creating cold spots.

- Dryness Fraction Test

Ensures that the steam has an appropriate moisture content. Too much or too little moisture can reduce sterilization effectiveness or damage the load.

- Superheat Test

Identifies the presence of superheated steam which may delay condensate formation, reducing sterilization efficiency.

- Pure Steam Condensate Analysis (if required)

Evaluates conductivity, TOC, endotoxins, pH, and silica levels to confirm steam purity for use in cleanroom and aseptic processes.

Where It Applies:

- Autoclaves (Horizontal/Vertical/SIP units)

- Pure Steam Generators

- Sterilizers (GMP compliant, vacuum or gravity)

- Steam-In-Place (SIP) Systems

- Cleanroom HVAC Steam Humidifiers

- Lyophilizers (Steam sterilization chambers)

Why Oorja?

- Use of NABL-calibrated instruments and traceable test equipment

- Experienced team with on-site testing capability

- Compliance with EN285, ISO 17665, HTM 2010, USP standards

- Comprehensive documentation including validation reports, graphs, and interpretations

- Root cause analysis in case of deviation or failure in parameters

- Fast turnaround time and audit-ready reports

With Oorja Technical Services Pvt. Ltd., you can be confident in the quality, reliability, and performance of your sterilization process — ensuring patient safety, product efficacy, and complete regulatory compliance.

.